The Quad® Brand Seal Family

The Quad® Brand Seal Family

Standard Products and Common Configurations

Minnesota Rubber and Plastics produces a complete family of Standard O-Ring, Quad-Rings® Brand and custom seals to provide the optimum seal for a wide range of applications. Our original four-lobed Quad-Ring® Brand seal design has been expanded into a complete line of custom seals, some patented, with unique features to handle the most difficult sealing requirements.

Quad® Brand O-Rings (standard and custom molded)

For general sealing applications, Quad® Brand O-Rings usually are a good first choice. Minnesota Rubber and Plastics offers a full range of sizes in Nitrile and Fluoroelastomer materials as standard products. If your application requires other elastomers, Minnesota Rubber and Plastics will help you select the right material and custom mold it to the required specifications.

Quad-Ring® Brand Seals (standard and custom molded)

Providing excellent sealing characteristics in a broad range of applications, Minnesota Rubber and Plastics’ original four-lobed designed seals are available in a full range of standard sizes, in Nitrile and Fluoroelastomer materials. Should your application require other elastomers, Minnesota Rubber and Plastics will help you select the right material and custom mold it to the required specifications.

- Twice the Sealing Surface. Quad-Ring® Brand seals have a unique multiple point seal contact design. With two sealing surfaces, there is greater seal protection when used as an ID seal, OD seal, or face seal.

- Lower Friction because of the Quad-Ring® Brand seals’ multiple point seal contact design, less squeeze is required to maintain an effective seal. This lower squeeze results in lower friction, an important consideration for dynamic sealing applications.

- Longer life because of reduced squeeze. Quad-Ring® Brand seals last longer and promote system “uptime.” Equipment operates longer and requires less maintenance.

- Seal surface free from parting line insures no leakage across the parting line. Parting line is in the valley not on the sealing surface like conventional O-Rings.

- No spiral twist. Four lobe shaped Quad-Ring® Brand seals eliminate spiral twist which causes conventional O-Rings to rupture.

Modified Quad-Ring® Brand Seals (custom molded)

For sealing across a broader tolerance range, the Modified Quad-Ring® Brand seal has a deeper valley than the original Quad-Ring® Brand seal design, thereby producing a lower deflection force. In OEM applications such as plastic housings, this seal design has reduced load with less creep. Designed for pressures less than 120 psi (8.1 bar). Modified Quad-Ring® Brand seals recently were granted a new patent.

Quad-O-Dyn® Brand Seals (custom molded)

For dynamic sealing applications providing near zero leakage at pressures to 2000 psi (138 bar) and higher. This six-lobed configuration, designed with two primary and four backup sealing surfaces, has excellent sealing features in very difficult applications. It can be used with standard O-Ring grooves.

Quad-Bon® Brand Seals (custom molded)

Ideal for applications with oversized grooves, strong spiraling pressures and as a retrofit for existing O-Ring applications. This four-lobed configuration has the widest valley in our custom cross section product line. It provides excellent sealing features.

Quad-Kup® Brand Seals (custom molded)

For high diameteric clearance applications and those requiring low operating friction. Provides low-pressure seal up to 150 psi (10.3 bar) in reciprocating and rotary applications. The combination lobed/cup configuration can be designed with the lip on any of the four surfaces, top or bottom, on the ID or OD.

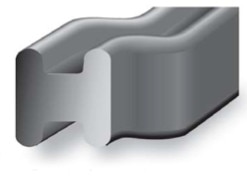

H-Seals (custom molded)

Ideal for intricate single or multiple groove configurations in static face seal applications. With the deepest valley of all Minnesota Rubber and Plastics product designs, this configuration has superior sealing features in difficult applications.

Quad®-O-Stat Brand Seals (custom molded)

Designed specifically for static face sealing applications. Each of the six lobes serves as an individual seal with the corner lobes functioning as seal backups to the central lobes. If one lobe fails, the remaining lobes provide zero leakage sealing. Can be installed in standard O-Ring grooves.

Quad® P.E. Plus Brand Seals (custom molded)

This dual-function seal forms a self-lubricating seal and an elastomeric spring for both rotary and reciprocating applications. Newly patented, this seal design combines injection moldable thermoplastic bearing material with a Quad-Ring® Brand seal. This seal is not intended for zero leakage applications.