Polyisoprene

Polyisoprene Natural (NR) and Synthetic (IR)

Polyisoprenes, both natural (from trees) and synthetic, are noted for outstanding resilience, resistance to tear and abrasion, excellent elasticity, and flex fatigue resistance.

Polyisoprenes also have excellent tensile strength characteristics and are operable in low temperature -65°F (-54°C) environments. Polyisoprenes are not recommended for high heat, ozone, sunlight, petroleum, or hydrocarbon environments.

The two isoprenes differ slightly; the purity of synthetic polyisoprene provides more consistent dynamic properties with better weather resistance. Synthetic polyisoprene’s lack of “tree” organics also gives a relatively odorless rubber. Natural rubber, when compared to synthetic, provides slightly better properties in tensile strength, tear resistance, compression set, and flex fatigue resistance.

Compounds 352AP

- “General purpose” isoprene compounds

- Excellent tear and abrasion resistance

- Excellent vibration isolating material

- Outstanding resilience and flex fatigue resistance

| Compound | Hardness Shore A | Tensile MPa | Tensile psi | Elongation (%) |

|---|---|---|---|---|

| 352AP | 40 | 10.3 | 1500 | 500 |

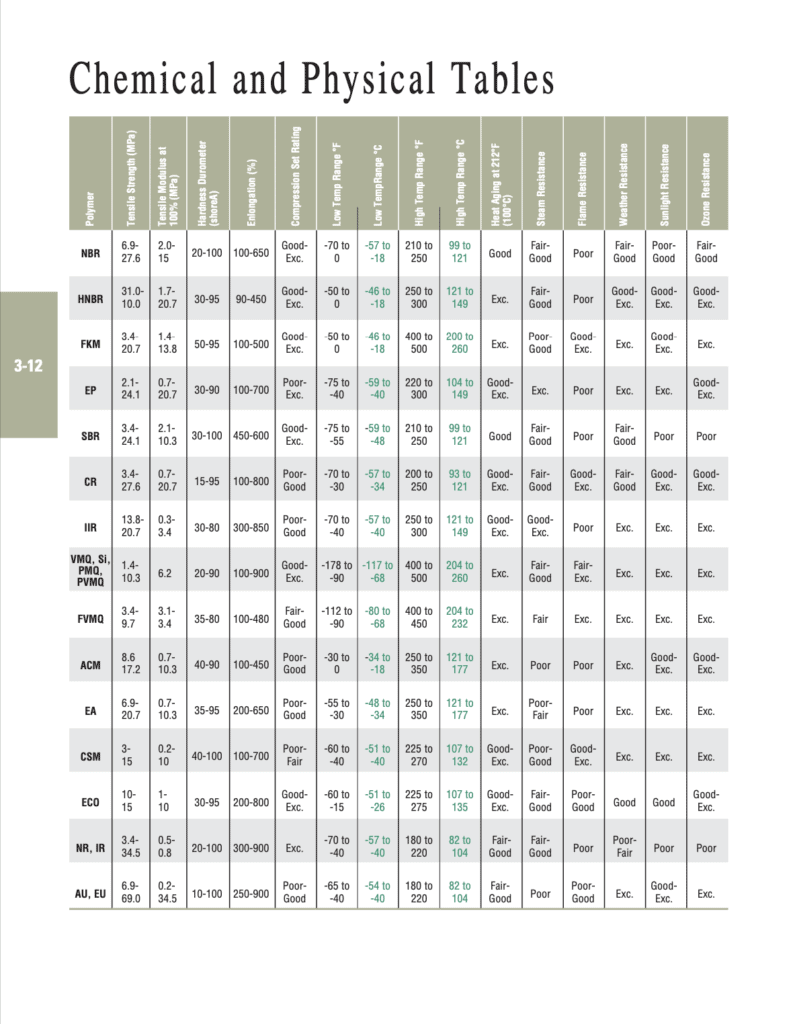

Chemical and Physical Tables

Click below to view the Elastomers/Materials: Chemical and Physical Tables PDF