Where to Start

Here are a few suggestions for beginning the process of material selection:

| Application Type | Hardness Range (Shore A) |

|---|---|

| Sealing Applications (depending on pressure) | 60 – 80 |

| Flow Controllers | 50 – 70 |

| Umbrella/Duckbill Check Valves | 50 – 60 |

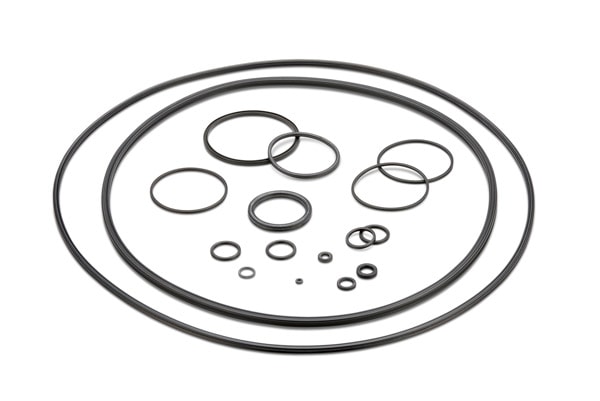

- If you are selecting a material for an O-Ring or Quad-Ring®, consider one of the two standard, “off-the-shelf” Minnesota Rubber & Plastics materials, 366Y, (a 70 Shore A nitrile rubber,) or 514AD, (a 70 Shore A fluoroelastomer rubber.) These are suitable for many industrial applications and are readily available.

- Nitrile rubber is a good general purpose rubber.

- If you are designing a potable water application, consider the use of an EP rubber, as long as the rubber will not come in contact with hydrocarbon based oils and greases, which will cause it to swell and degrade.

- If you are designing a medical application involving human contact or high cleanliness requirements, consider the use of a silicone rubber.

- If your application will experience temperatures greater than 300° F (150° C) in an industrial environment, a fluoroelastomer may be a good choice.