Corners and Edges

When designing rubber parts, sharp corners are generally undesirable.

A part’s corners should be broken with as gentle a radius as possible, preferably one greater than 0.050 inches, although radii as small as 0.010 inches are possible.

A sharp corner increases the difficulty (and therefore the cost) of machining the mold and can potentially affect product quality by increasing the likelihood of certain types of molded defects.

It is preferred that a part’s edges, where they coincide with a parting line, should be sharp. This simplifies the mold construction. Radii, when necessary or desired, however, can usually be added by relocating the part line.

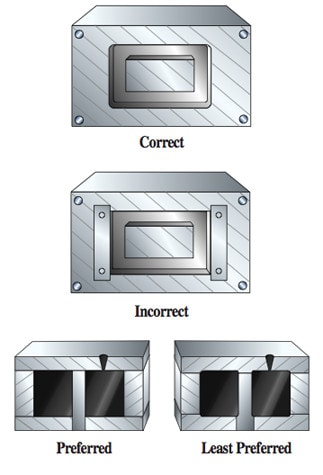

The preferred methods for designing corners and edges are illustrated in the following figures:

Corners: When viewed from the top, the part should display round corners.

Edges: When seen from the side, the edges should be square.