Warpage

- Designing Rubber Components

- Overview

- Working Together

- Engineering Design

- Cost Effective Custom-Molded Seals

- Avoiding Rubber Component Design Problems

- Properties in Balance

- Selecting an Elastomeric Material

- Elastomer Hardness Selection

- Where to Start

- Corners and Edges

- Undercuts

- Holes

- Sharp Edges

- Circularity

- Total Indicator Reading

- Rubber Over-Molding

- Standard Tolerance Chart

- Rubber Molding Considerations

- Building the Mold

- Molding Processes

- Deflashing

- Gates

- Feed Examples

- Building a Prototype

- Selecting the Mold

- Parts Assembly and Prototype Testing

- Specifying Metal Parts

- CAD Data Interchange Capabilities

- Elastomers/Materials

- Overview

- Polymer Types

- Acrylonitrile / Butadiene

- Highly Saturated Nitrile

- Nitrile / PVC Resin Blends

- Fluorocarbon

- Ethylene Propylene Diene Monomer

- Styrene Butadiene

- Polychloroprene

- Isobutylene Isoprene Rubber

- Silicones

- Fluorosilicone

- Polyacrylate

- Ethylene Acrylic

- Chlorosulfonated Polyethylene

- Epichlorohydrin

- Polyisoprene

- Polyurethane

- Polybutadiene

- Special Compounds & Certifications

- Wear Resistant/ Lubricated Compounds

- Quniton®

- FDA Regulations/Food & Beverage Applications

- UL Listed Compounds

- NSF International® Potable Water Applications (ANSI/NSF Standard 61)

- International Certifications – Potable Water

- Rubber Resistance to Chlorine and Other Water Treatment Chemicals

- Perfluoroelastomers

- Medical and Laboratory Requirements

- Taste and Odor Specifications

- FKM Compounds for Fuel and Chemical Industries

- Computer Applications

- Designing Plastic Components

- Plastic & Thermoplastic Materials

- Rubber Standard Parts

- Overview

- Rubber Standard Profiles

- The Quad® Brand Seal Family

- Identifying A Sealing Application Type

- Defining Factors in Sealing Applications

- Quad-Ring® Brand Seals

- Groove Design: Quad-Ring® Seals

- Quad® Brand O-Ring Seals

- Groove Design: O-Ring Seals

- Piston Seal Application Example

- Rod Seal Application Example

- Quad-Ring® Brand and O-Ring Seals for Face Seal Applications

- Quad-Ring® Face Seal Application Example

- Rotary Seals

- Sealing Systems Rotary Seal Application

- Quad-Ring® Brand Seals for Rotary Applications With Oil

- Quad-Ring® Brand Rotary Seal Application

- Selection Guide/Standard Size Quad-Ring® Brand Seals and Quad® Brand O-Rings Seals

- Quad® Brand Ground Rubber Balls

- Equi-Flex™ Rod Wiper/ Scraper

- Quad® P.E. Plus Brand Plastic Exclusion Seals

- Glossary of Terms

- Pawling Products

- Overview

- Inflatable Seals and Clamps

- Inflatable Seal Standard Profiles

- Q Standard Profiles

- Inflatable Seal and Clamp Construction

- Inflatable Seal and Clamp Configurations

- Recommended Inflatable Sealing Gap

- Inflatable Seal Corner Details

- Inflatable Clamp (or Seal) End Designs

- Inflatable Seal Air Connectors

- Universal Air Connectors

- Inflatable Seal and Clamp Custom Capabilities

- Compression Seals & Gaskets

- Septa

- Materials

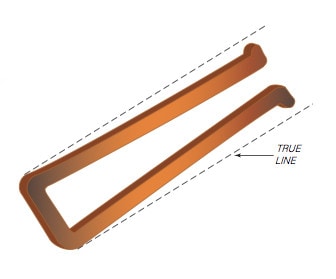

Some warpage can be expected with any molded plastic part.

The amount of warpage will vary with the type of thermoplastic material being used.

A good rule of thumb for most material and part configurations is 0.010 distortion per 3.00 part length (0.033mm/cm).