Case Study

How Overmolding Improves Product Performance

Creating molded rubber parts with inserts involves considerable preparation before and after molding. These tips can help ensure a durable finished part while minimizing production costs.

Overmolding deserves more credit than it gets for improving the performance of today’s products. Every industry benefits from this process as designers find new and better ways using overmolding to make designs perform longer and more effectively. The following overmolded products demonstrate important benefits, setting them apart from earlier non-overmolded products.

For this anti-vibration mount, overmolding isolates and cushions the sink disposer. The improvements brought about by this design reduced noise and vibration. The mounting device was designed to provide the mounting platform and seal for the disposer. Previous designs were made of plastic or stamped metal and were noisy when used. The new design is robust so that the disposer attaches securely to the sink and provides the required sealing function to handle hot and cold liquids and all types of food disposal.

Finite element analysis was used to develop an overmolded design that would meet softness, toughness, and durability requirements. The primary component in the overmolded three-piece assembly is a stamped stainless steel ring that has a crimped rim that fits over and locks onto the disposer housing. A flange inside the steel ring positions and holds a plastic ring in place and around which the elastomer seal is molded.

Prior to the assembly and rubber overmolding, both steel and plastic ring components are put through an automated cleaning process. A bonding adhesive is then applied to hold the plastic ring inside the steel ring. Using automated assembly equipment designed for the project, the two assembled components are then inserted into an automated vertical molding press where the proprietary elastomer formulation is injected into the mold cavity. The heated elastomer flows around the metal ring bonding all of the components together. When cooled, the elastomer forms the sealing and vibration-damping ring integrated and bonded securely to the stainless steel mounting ring.

When complete, the bond between components is impervious to leaks, invasion by food particles and resistant to solvents. Since no fasteners or connecting devices are used in the assembly, there are no gaps or spaces anywhere eliminating any chance for bacteria traps or for vibration to loosen the components.

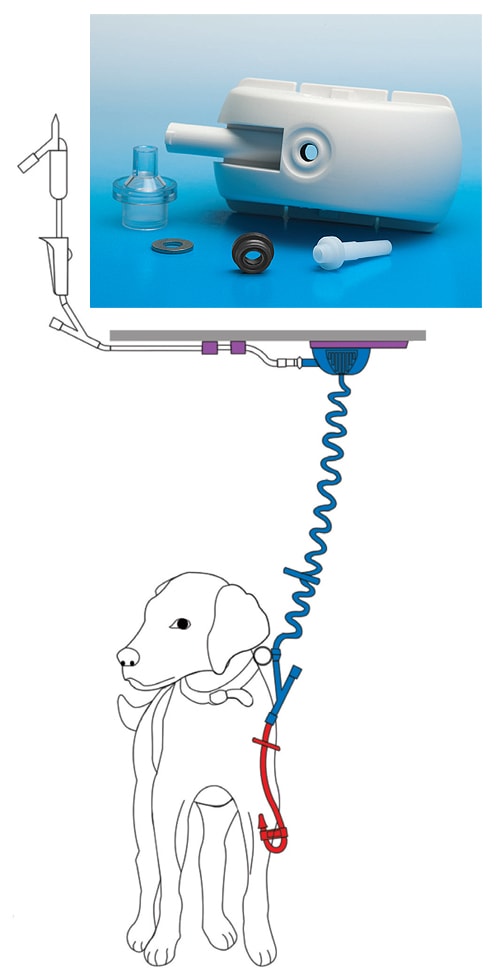

The product is made up of eight special grade polycarbonate material components and a thermoplastic elastomer (TPE) bellows. The main body and cover have male/female hinges molded along one side. They mate precisely when assembled so opening and closing is smooth and the seal is weather-tight.

Small fingers strategically positioned in the interior body and door locate, snap, and lock components together tightly without the need for special fasteners. One end of the flexible bellows slides over and is overmolded and ultrasonically welded onto the door, which provides a tight seal when closed around the housing edges.

Overmolding medical instruments improves use

Medical, dental and orthopedic instruments benefit from overmolding. Features previously difficult or impossible to incorporate into medical product designs such as a lubricious surface finish can facilitate insertion of a medical device.

In contrast, a slightly tacky surface will improve grip of surgical instruments for tactile sensitivity and better instrument control. The overmolded design can enhance the safety of the instrument, improve design ergonomics as well as facilitate function.

Custom colorization is another overmolding benefit for aluminum and stainless steel instruments. This provides easy identification and instrument separation in the medical setting. Also, many overmolding formulations have good impact resistance and are available in a full range of material durometers. For repeat use instruments, many Silicone overmolding materials are autoclavable. To meet FDA requirements, many overmolding material formulations are USP Class 6 and ISO 10993 implantable grades.

Tips for rubber overmolding

Steel, brass, aluminum, or plastic subcomponents are often incorporated into overmolded rubber parts. These subcomponents are commonly termed inserts, as they are “inserted into the mold.” Typical metal inserts include screw machine parts, metal stampings, and powdered metal shapes.

When designing rubber overmolded parts, keep the following design principles in mind:

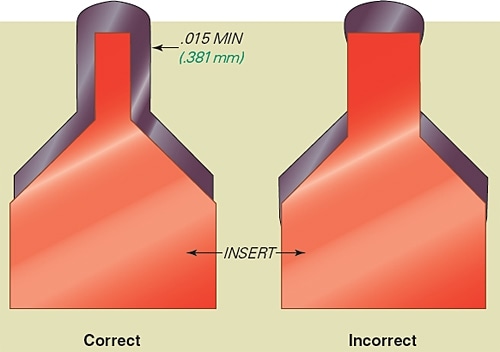

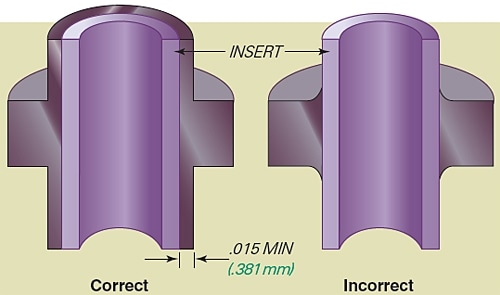

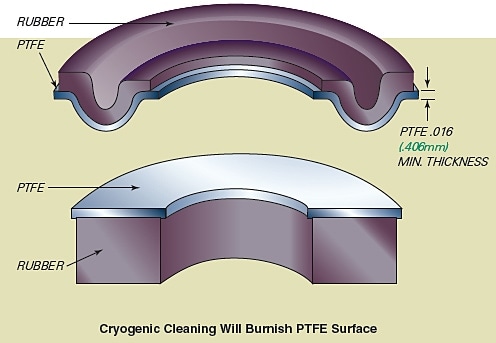

- Encapsulate as much of the surface of the insert in rubber as possible, with a minimum specified rubber thickness of 0.020 in. (0.51 mm). This coverage helps to ensure maximum bonding and control flash formation.

- Avoid shutting rubber flow off on vertical surfaces and provide proper lands (steps).

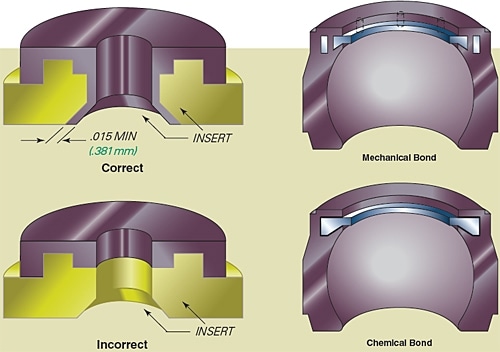

- The rubber can be molded to the insert by means of mechanical or chemical bonding. Mechanical bonding involves the incorporation of holes, depressions or projections in the insert itself. The rubber flows around or through the insert during the molding process to create a bond.

Special adhesives can be applied to the insert prior to molding to create a strong chemical bond.

Inserts designed for use in demanding applications are often attached to the rubber part using a combination of mechanical and chemical bonding.

Summary

Not only are seals important in medical device applications, they are often the very heart of the device and its successful use. Original equipment manufacturers should follow a scientific, data-based approach for seal development. Selecting the material, designing the part, testing and validating the designs are all essential steps in a successful seal program. Such a program requires the early assistance of companies with deep knowledge and experience in rubber materials and sealing applications. This requires a team approach to achieve a common goal.