Rubber Molding Considerations

The manufacturing of rubber parts is accomplished in one of three ways: Compression Molding, Transfer Molding or Injection Molding.

The choice of manufacturing process depends on several factors, including the size, shape and function of the part, anticipated quantity, type, and cost of the raw material. The three methods, however, share certain basic characteristics that are important to understand when designing custom molded rubber parts.

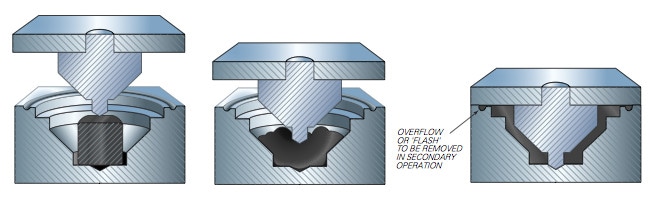

Rubber Compression Molding

The rubber compression molding process is not unlike making a waffle. A surplus of material must be placed in the cavity to ensure total cavity fill. Heat and pressure are applied, causing the compound to flow, filling the cavity and spilling out into overflow grooves.

Compression molding is often chosen for medium-hardness compounds – in high volume production, or applications requiring particularly expensive materials.

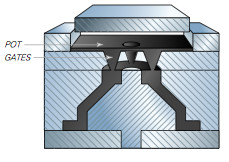

Rubber Transfer Molding

Transfer molding differs from compression molding in that the material is placed in a pot, located between the top plate and plunger. The material is squeezed from the pot into the cavity through one or more orifices called gates, or sprues.

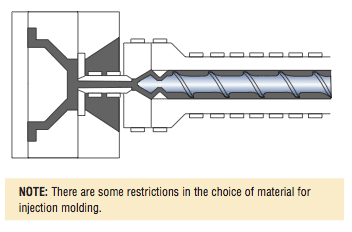

Rubber Injection Molding

Injection molding is normally the most automated of the molding processes. The material is heated to a flowing state and injected under pressure from the heating chamber through a series of runners or sprues into the mold. Injection molding is ideal for the high volume production of molded rubber parts of relatively simple configuration.