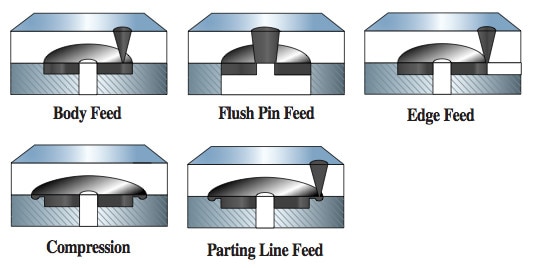

Feed Examples

- Designing Rubber Components

- Overview

- Working Together

- Engineering Design

- Cost Effective Custom-Molded Seals

- Avoiding Rubber Component Design Problems

- Properties in Balance

- Selecting an Elastomeric Material

- Elastomer Hardness Selection

- Where to Start

- Corners and Edges

- Undercuts

- Holes

- Sharp Edges

- Circularity

- Total Indicator Reading

- Rubber Over-Molding

- Standard Tolerance Chart

- Rubber Molding Considerations

- Building the Mold

- Molding Processes

- Deflashing

- Gates

- Feed Examples

- Building a Prototype

- Selecting the Mold

- Parts Assembly and Prototype Testing

- Specifying Metal Parts

- CAD Data Interchange Capabilities

- Elastomers/Materials

- Overview

- Polymer Types

- Acrylonitrile / Butadiene

- Highly Saturated Nitrile

- Nitrile / PVC Resin Blends

- Fluorocarbon

- Ethylene Propylene Diene Monomer

- Styrene Butadiene

- Polychloroprene

- Isobutylene Isoprene Rubber

- Silicones

- Fluorosilicone

- Polyacrylate

- Ethylene Acrylic

- Chlorosulfonated Polyethylene

- Epichlorohydrin

- Polyisoprene

- Polyurethane

- Polybutadiene

- Special Compounds & Certifications

- Wear Resistant/ Lubricated Compounds

- Quniton®

- FDA Regulations/Food & Beverage Applications

- UL Listed Compounds

- NSF International® Potable Water Applications (ANSI/NSF Standard 61)

- International Certifications – Potable Water

- Rubber Resistance to Chlorine and Other Water Treatment Chemicals

- Perfluoroelastomers

- Medical and Laboratory Requirements

- Taste and Odor Specifications

- FKM Compounds for Fuel and Chemical Industries

- Computer Applications

- Designing Plastic Components

- Plastic & Thermoplastic Materials

- Rubber Standard Parts

- Overview

- Rubber Standard Profiles

- The Quad® Brand Seal Family

- Identifying A Sealing Application Type

- Defining Factors in Sealing Applications

- Quad-Ring® Brand Seals

- Groove Design: Quad-Ring® Seals

- Quad® Brand O-Ring Seals

- Groove Design: O-Ring Seals

- Piston Seal Application Example

- Rod Seal Application Example

- Quad-Ring® Brand and O-Ring Seals for Face Seal Applications

- Quad-Ring® Face Seal Application Example

- Rotary Seals

- Sealing Systems Rotary Seal Application

- Quad-Ring® Brand Seals for Rotary Applications With Oil

- Quad-Ring® Brand Rotary Seal Application

- Selection Guide/Standard Size Quad-Ring® Brand Seals and Quad® Brand O-Rings Seals

- Quad® Brand Ground Rubber Balls

- Equi-Flex™ Rod Wiper/ Scraper

- Quad® P.E. Plus Brand Plastic Exclusion Seals

- Glossary of Terms

- Pawling Products

- Overview

- Inflatable Seals and Clamps

- Inflatable Seal Standard Profiles

- Q Standard Profiles

- Inflatable Seal and Clamp Construction

- Inflatable Seal and Clamp Configurations

- Recommended Inflatable Sealing Gap

- Inflatable Seal Corner Details

- Inflatable Clamp (or Seal) End Designs

- Inflatable Seal Air Connectors

- Universal Air Connectors

- Inflatable Seal and Clamp Custom Capabilities

- Compression Seals & Gaskets

- Septa

- Materials

The number, size and location of gates in even the simplest mold design can vary greatly depending on the molding process. Specifications such as hardness of the material, dimensional tolerances, cosmetic consideration, and customer requirements will impact gates in a design.

Illustrated here are 5 of the most common mold configurations: