Quad® P.E. Plus Brand Plastic Exclusion Seals

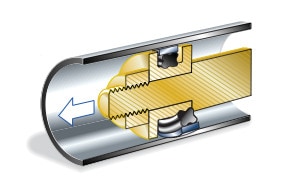

The Quad® P.E. Plus Brand is a patented seal design that combines an injection-molded thermoplastic bearing material with a Quad-Ring® Brand seal, O-ring, or custom seal to form a self-lubricating seal for both rotary and reciprocating seal applications.

This seal can be used in applications where some leakage is permissible.

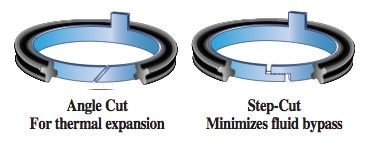

A tab on the thermoplastic ring locks it into the housing or shaft to prevent independent movement of the seal assembly. The ring is split to allow for thermal expansion of the shaft or cylinder.

Materials used for the custom-molded Quad® P.E. Plus Brand seal can be specified from a wide range of rubber compounds and high performance thermoplastics.

The characteristically high pressure-velocity values and low coefficients of friction of thermoplastic bearing materials make them ideal for high velocity applications. These thermoplastics are also self-lubricating, which means that a Quad® P.E. Plus Brand seal can be used in continuous applications without external lubrication, a condition that would cause other seals to either burn up quickly, or destroy the surface of the cylinder or shaft it was meant to protect. Versions of the Quad® P.E. Plus Brand seal can be designed to operate in:

- Nonlubricated rotary applications with up to 1200 fpm (457.2 M/min) surface speeds

- Pressure lubricated rotary applications with up to 6500 fpm (1981.2 M/min) surface speeds

- Continuous temperature up to 450°F (232°C)

- Nonlubricated reciprocating applications with an operating life of more than 15 million cycles.

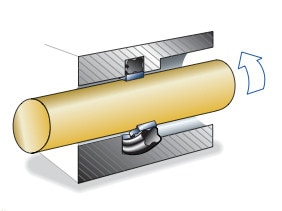

For rotating shafts

For rotary applications, the thermoplastic ring is split at an angle to allow for thermo-expansion of the metal surface. The thermoplastic ring can also be designed with a step-cut to minimize fluid bypass. Placed in the housing or on the shaft, the rubber seal squeezes the thermoplastic ring snugly against the sealing surface. The tab on the thermoplastic ring fits into a slot in the groove and prevents the seal from rotating.

Reciprocating Applications

In reciprocating applications, the rubber seal is installed in a groove on the piston (on the ID of the thermoplastic ring) and presses the thermoplastic ring firmly against the cylinder wall. The ring is split to compensate for thermal expansion.