Superior Performance

For applications that include unique or demanding requirements, a high performance polymer often provides an effective material and design solution.

From mechanical to unique thermal properties, high performance polymers provide design engineers with valuable design and end use options.

Performance Attributes

- Chemical resistance

- Conformability

- Dimensional stability

- Flexibility

- Injection moldable

- Lightweight

- Metal replacement

- Noise reducing

- Self lubricating

- Temperature extremes

End Use Applications

- Bearings

- Bushings

- Retainers

- Thrust plates

- Thrust washers

- Rotary seal rings

- Gears

- Poppets

Application Environments

- Valves

- Pumps

- Compressors

- Fuel systems

- Transmission

- Steering systems

- Suspension systems

- Torque converters

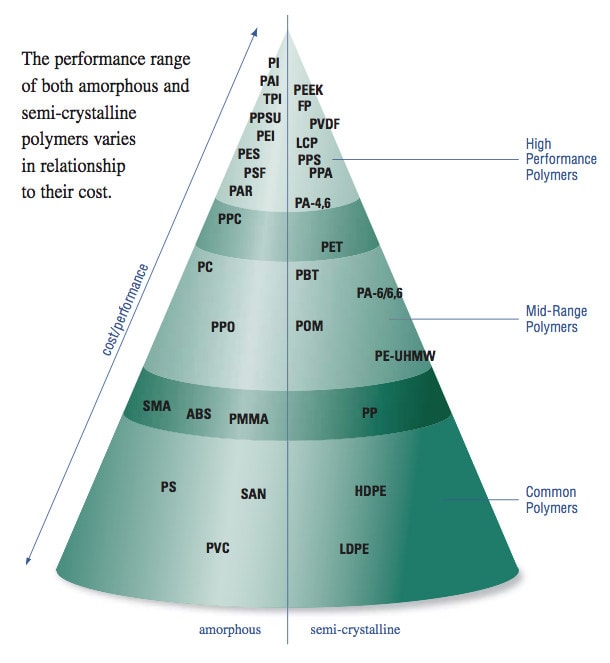

This performance and cost illustration is a partial list depicting the spectrum of low-end to high-end performance materials.

| Abbreviation | |

|---|---|

| ABS | acrylonitrilebutadienestyrene |

| FP | fluoropolymers |

| HDPE | high density polyethylene |

| LCP | liquid crystal polymers |

| LDPE | low density polyethylene |

| PA-4,6 | polyamide-4,6 |

| PA-6/6,6 | polyamide-6/6,6 |

| PAI | polyamideimide (Torlon®) |

| PAR | polyarylate |

| PBT | polybutylene terephthalate |

| PC | polycarbonate |

| PE-UHMW | ultrahigh molecular weight polyethylene |

| PEEK | polyetheretherketone |

| PEI | polyetherimide |

| PES | polyethersulfone |

| PET | polyethylene terephthalate |

| PI | polyimide (Aurum®) |

| PMMA | polymethyl methacrylate |

| POM | polyoxymethylene (also polyacetal) |

| PP | polypropylene |

| PPA | polyphthalamide |

| PPC | polyphthalate carbonate |

| PPO | polyphenylene oxide |

| PPS | polyphenylene sulfide |

| PPSU | polyphenylsulfone |

| PS | polystyrene |

| PSF | polysulfone |

| PVC | polyvinyl chloride |

| PVDF | polyvinylidene fluoride |

| SAN | styrene acrylonitrile |

| SMA | styrene maleic anhydride |

| TPI | thermoplastic polyimide |